Maquinas De Coser Usadas

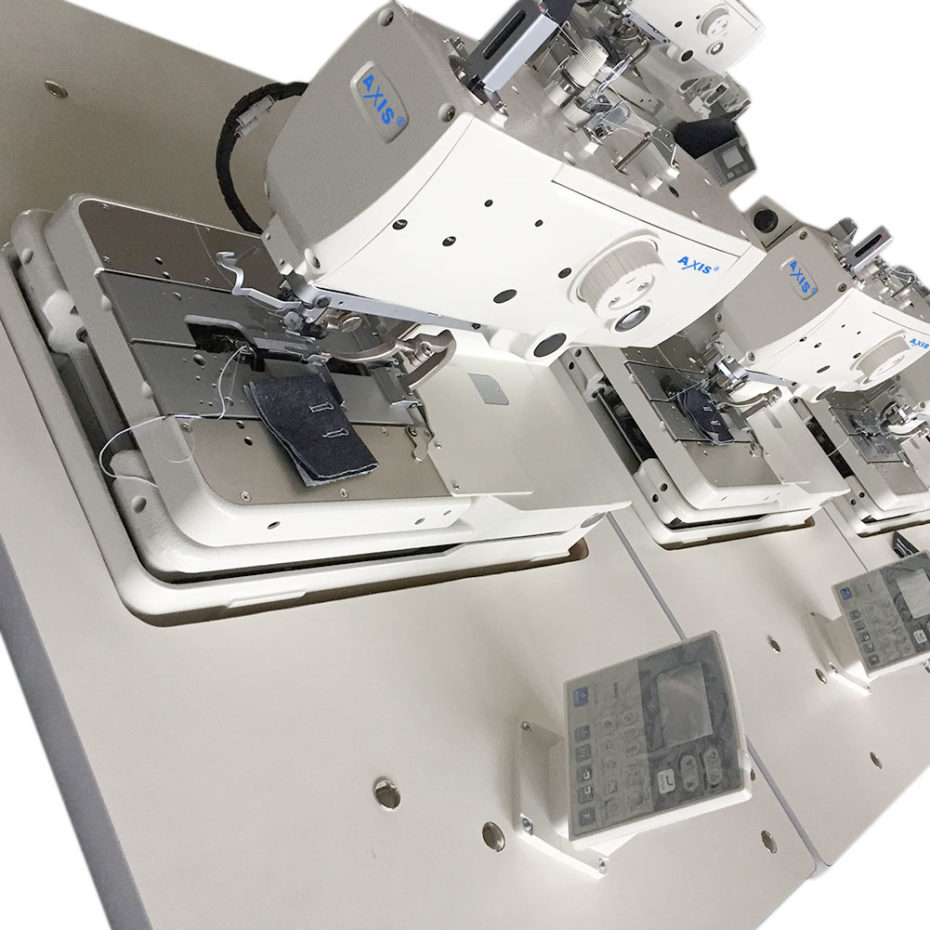

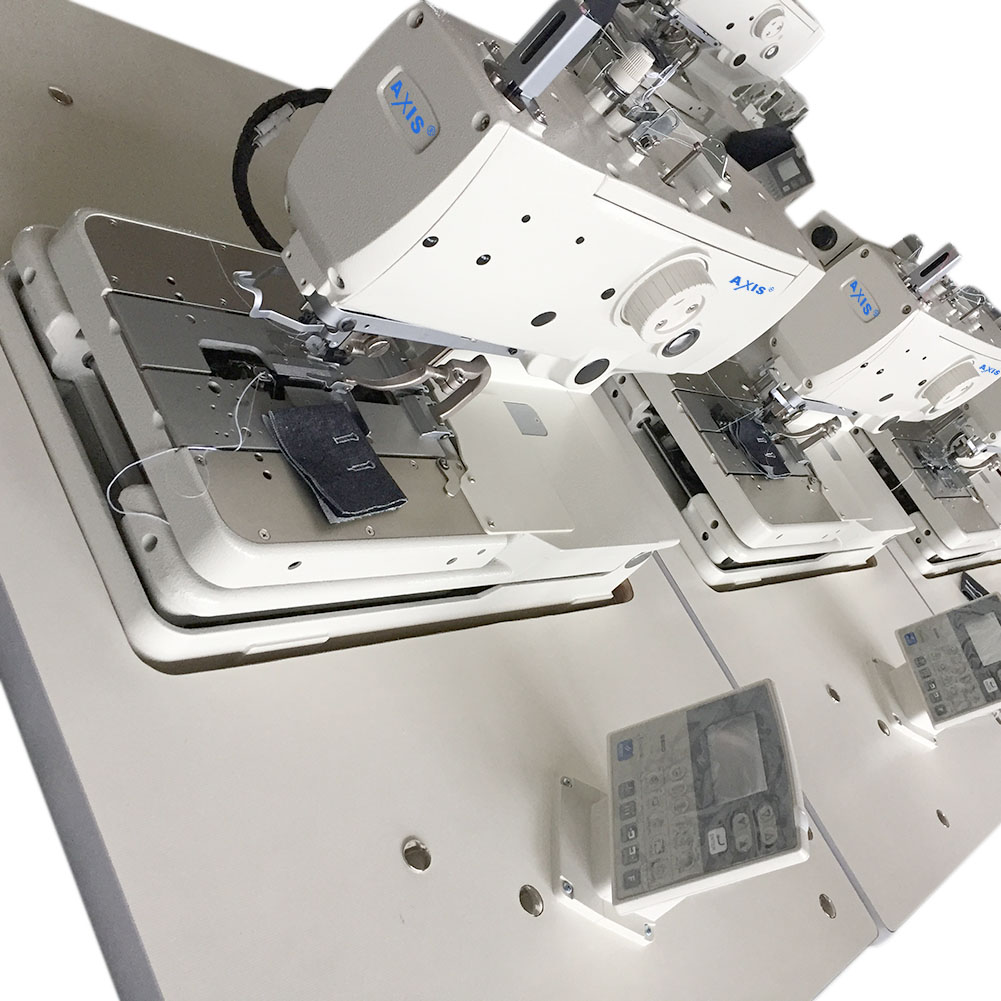

AXIS Rh 9820 Eyelet buttonhole sewing machine

Axis RH 9820 sewing machine

RH 9820 sewing machine Electronic eyelet button hole

1.Rh 9820 sewing machine computereized system is 100% same as brothers ,

2.STRONG H knife A quality

3.JAPAN TIMING BELT

4.80 % SPARE PARTS ARE FROM BROTHER SPARE PARTS MANUFACTORIES

Fine stitches are available

Precision of stitch point has been improved

Skipped stitches are reduced

Large arm pocket providing ease of operation

Sewing with less noise

Easy maintenance

Centralized lubrication system

Thread waste can be collected

Eyelet cloth chips can be cleared

Operation panel easy to use for everyone

electronic eyelet buttonhole machine

electronic eyelet buttonhole sewing machine

rh 9820 sewing machine

| Specifications | Axis 9820-00 | Axis 9820-01 | Axis 9820-02 | ||

| L2230 | L1826*1 | ||||

| Thread

trimmer |

Upper thread

trimmer |

Long thread cut | Long thread cut | Short thread cut | |

| Lower thread

trimmer |

None | Long thread cut | Short thread cut | ||

| Main applications | Ladies’ wear | Men’s wear, casual wear | Jeans | Jeans, trousers | |

| Other applications | Men’s wear, casual wear, | Ladies’ wear, | |||

| jeans, trousers | jeans, trousers | ||||

| Features | Only the upper thread is cut by the | All the threads are cut long by the | All the threads are cut short by the | ||

| thread trimmer. Buttonholes up to | thread trimmers. The long thread | thread trimmers. This saves the | |||

| 50 mm long can be sewn. | ends can be securely held in the | trouble of manual trimming and | |||

| subsequent process. It is suitable | reduces consumption of the thread. | ||||

| for cases that require accurate | |||||

| short end or manual trimming. | |||||

| Sewing shape | |||||

| Sewing length | Eyelet buttonhole : 8-50 mm | Eyelet buttonhole : 8-42 mm | 22-30 mm | 18-26 mm | |

| Straight buttonhole : 5-50 mm | Straight buttonhole : 5-42 mm | L1422 (14-22 mm)*3 | L1422 (14-22 mm)*3 | ||

| L1826 (18-26 mm)*3 | L2230 (22-30 mm)*3 | ||||

| L2634 (26-34 mm)*3 | L2634 (26-34 mm)*3 | ||||

| L3442 (34-42 mm)*3 | L3442 (34-42 mm)*3 | ||||

| Length of work clamp (Standard) | 30 mm | 30 mm | 26 mm | ||

| Length of hammer (Standard) | 22 mm | 24 mm | 20 mm | ||

| Length of hammer (Accessory) | 30 mm | 28 mm | 24 mm | ||

| Sewing speed | 1,000-2,500 sti/min | ||||

| Stitch pitch | 0.5-2.0 mm | ||||

| Zigzag width | 1.5 – 5.0 mm (Up to 4.0 mm in mechanical, up to 5.0 mm with zigzag width compensation) | ||||

| Zigzag width (Factory setting) | 2.5mm | 3mm | |||

| Taper bartack length | 0-20mm | ||||

| Height of work clamp | 12 mm as standard (Available up to 16 mm) | 16mm | |||

| Starting method | Foot switch (Treadle type, Two-pedal type), Hand switch (Two-lever type) | ||||

| Feed mechanism | Intermittent feed by 3 pulse motors (X, Y,θ) | ||||

| Needle*4 | DOx558 Nm80 – Nm120 (SCHMETZ) | ||||

| Needle(Factory setting)*5 | DOx558 Nm100 | DOx558 Nm90 | DOx558 Nm110 | ||

| Languages supported | Japanese, English, Chinese, German, French, Spanish, Italian, | ||||

| for operation panel | Portuguese, Turkish, Indonesian, Vietnamese and Russian | ||||

| Safety equipment | Emergency stop function and built-in automatic stopping device activated by safety circuit in case of trouble | ||||

| Upper shaft motor | AC servo motor 550W | ||||

| Air pressure | Main regulator: 0.5 Mpa, Hammer pressure regulator: 0.4 MPa | ||||

| Air consumption | 43.2 l/min. (8 cycles/min.) | ||||

| Weight | Machine head: Approx. 120 kg.,Operation panel: Approx. 0.6 kg., Control box: 14.2-16.2 kg. (depending on the destination) | ||||

| Power supply | Single phase 100V/200V, 3-phase 200V/220V/380V/400V, 400VA | ||||

最近的评论