Maquinas De Coser Usadas

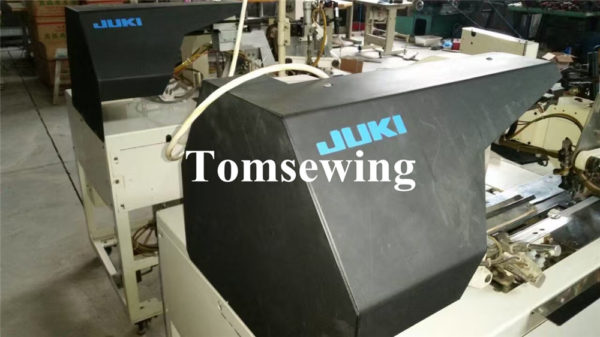

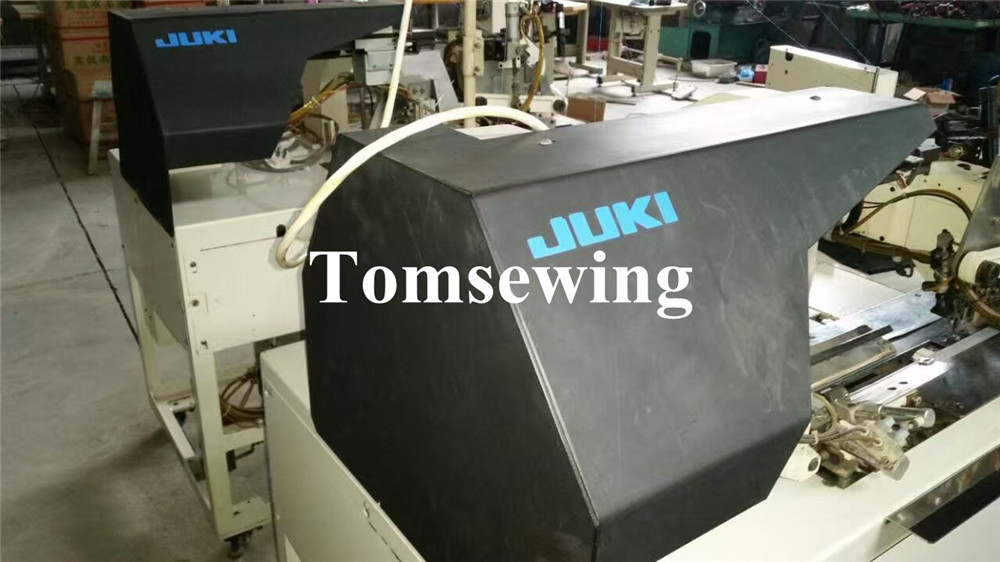

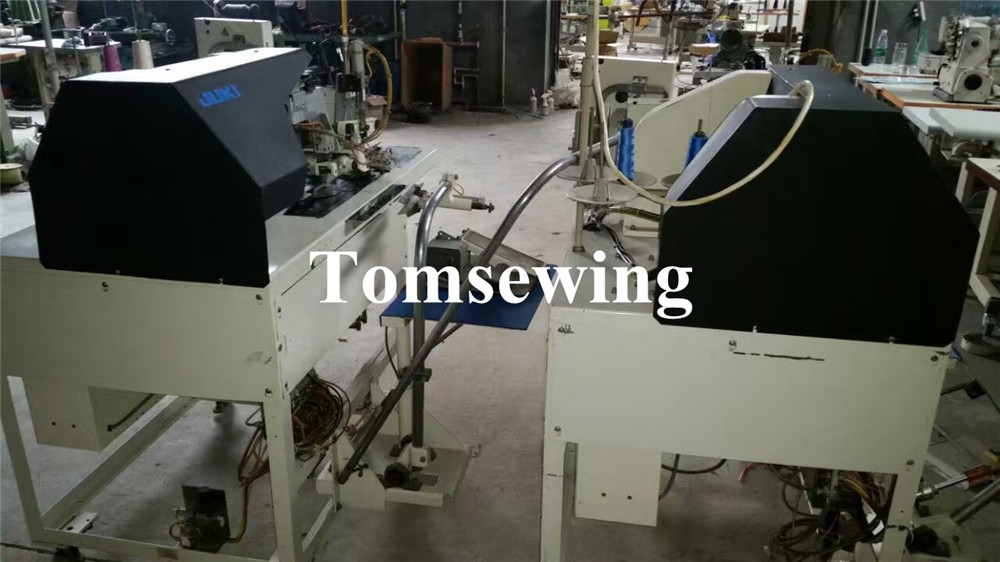

Used Juki Apw-195n Juki Apw Pocket Welt Machines

Used Juki Apw-195n Juki Apw Pocket Welt Machines

juki apw 195 pocket welt machines (7)

Used Juki Apw-195n Juki Apw Pocket Welt Machines

Used Juki Apw-195n Juki Apw Pocket Welt Machines

Used Juki Apw-195n Juki Apw Pocket Welt Machines

JUKI APW-195 second hand industrial sewing machine

The machine comes with a high-speed machine head which operates at a normal sewing speed as high as 2,500rpm.The clamp foot returns to its home position at a higher speed and the number of stitches sewn when the machine runs idle before coming to a complete stop at the end of sewing is reduced, thereby reducing the sewing time and dramatically increasing productivity. The machine’s operating efficiency is enhanced by its 1.6-fold capacity hook, which reduces time-consuming bobbin replacing works, and its monitoring device for the automatic detection of remaining bobbin thread, which is equipped as standard.

The machine also retains data on ten different patterns, including data on stitching length, stacker operation, etc..Cycle sewing with up to five combined patterns can be executed. With this feature, the machine offers higher productivity in welting on semi-custom-made garments under one-pattern-one-garment sewing system.

With its improved material-clamping force during jumping and its newly adopted fluorocarbon resin coated binder that provides smoother material feed, the machine can reliably feed garment bodies and welting patches made of slippery materials to the sewing position. The result is beautifully finished seams with no slippage between the garment fabric and welting patch.

lockstitch automatic welting machine

The machine offers improved welting capabilities and is compactly designed to allow efficient use in limited production spaces. In addition, by placing the clamp foot feeding mechanism on the top face of the table, obstacles are eliminated between the sewing table and clamp foot and a wider space is available under the arm. (Coats or raincoats can be placed on the machine in the lengthwise direction without folding.)

- Bobbin thread remaining amount detecting device

- By giving the operator a clear view of all the necessary sewing data, the machine’s liquid crystal display allows the operator to continue sewing uninterrupted

- Complete with table stand and motor

- Dart reference marking lamp

- Flap sewing type

- Maintenance works are conducted with the machine head tilted

- One of its main advantages is its outstanding workability

- Since the machine produces welts of consistent quality regardless of the welting length, it can be widely used for the continuous sewing of welts of different lengths

- The corner knife intervals can be automatically and accurately adjusted simply by setting a sewing length on the operation panel, ensuring that welts are finished with consistent quality at all times

- The machine is compactly designed to save space

- The machine prevents slippage between welting patches made of slippery materials

- The material is easily sucked in place through a hole in the main unit using the suction device and suction motor device in combination (both are optionally available)

- The most frequently used keys on the operation panel are upsized to facilitate data input

- Vacuum type table

- When attaching flaps, the flap sensor detects the flap length for the accurate adjustment of the sewing length and corner knife intervals

最近的评论